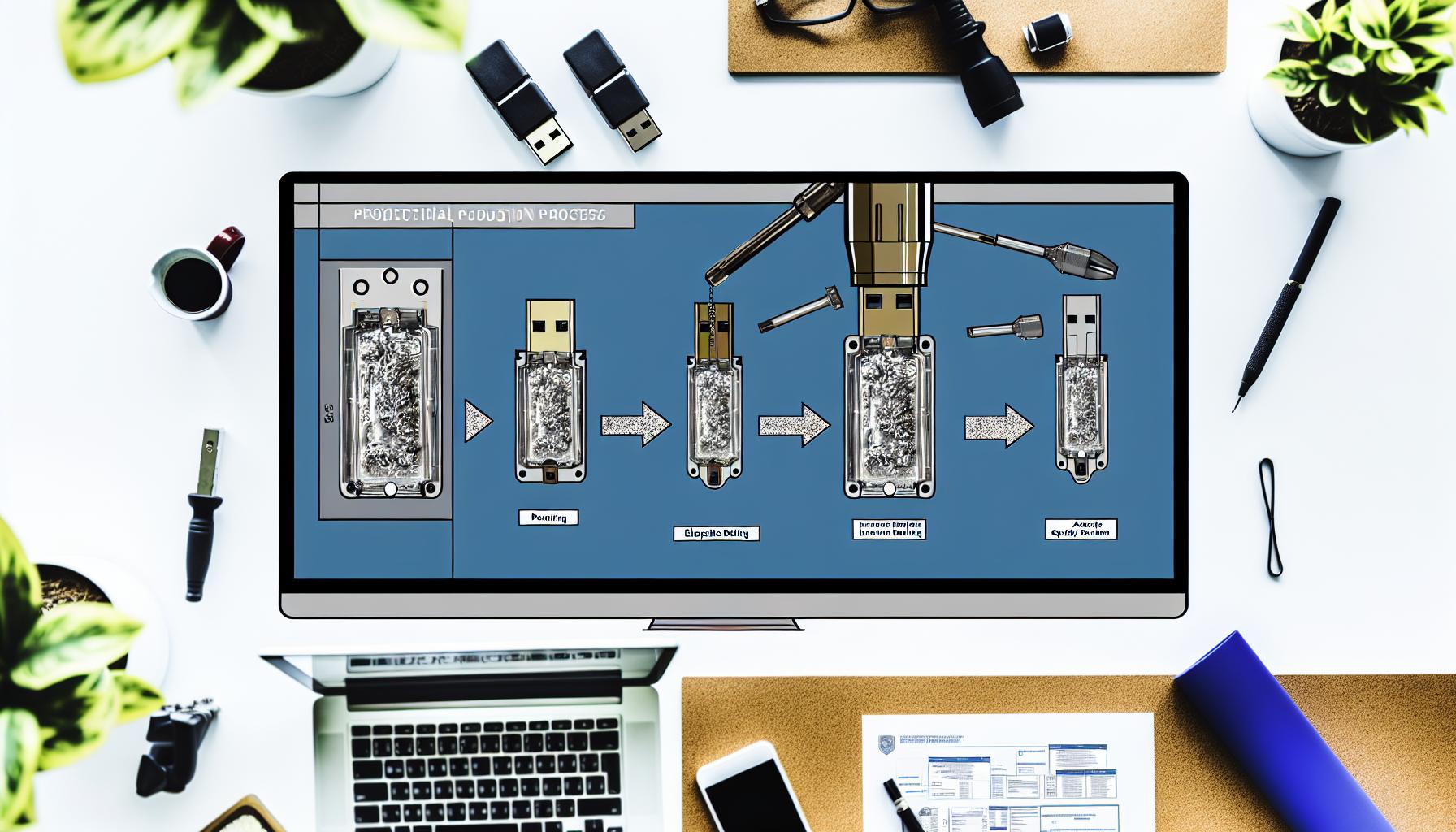

Detailed Explanation of USB Flash Drive Manufacturing Processes

As essential devices for modern data transfer and storage, the manufacturing processes of USB flash drives directly impact product performance and quality. This article provides an in-depth analysis of the key stages in USB production, focusing on the core procedures of USB manufacturing technology, offering practical production references for technical engineers and production managers.

I. Overview of the General USB Production Process

The production of a USB flash drive typically involves stages such as stamping, plating, injection molding, assembly, and quality inspection. These interconnected stages ensure both the structural integrity of the product and its electrical performance and aesthetic quality.

II. Stamping Process: Precision Manufacturing of Core Components

Stamping is the most fundamental and critical process in USB flash drive manufacturing, primarily used to produce the metal terminals and housing of the USB connector. Terminals are often made from highly conductive copper alloys, such as phosphor bronze or high-conductivity copper, formed by automated high-speed stamping presses from large copper coil strips. This process requires precise stamping dimensions and smooth edges to avoid burrs or deformation, which directly affects subsequent soldering and electrical contact performance.

Furthermore, the metal parts of the housing are formed by drawing round tubes through multiple sets of drawing dies, utilizing roller pressing and mandrel shaping to ensure the housing dimensions and shape comply with standards such as USB Type-C.

III. Plating Process: Enhancing Durability and Conductivity

After stamping, the metal terminals undergo plating to improve surface corrosion resistance and conductivity. Common plating materials include nickel and gold. The nickel layer increases hardness and provides oxidation resistance, while the gold layer ensures excellent electrical contact. Plating requires strict control of thickness and uniformity; excessive thickness can affect insertion/removal performance, while insufficient thickness reduces durability.

The plating stage also includes multiple cleaning and drying steps to ensure no impurities adhere, preventing any impact on the final product quality.

IV. Injection Molding Process: Structural Support and Exterior Formation

The plastic housing of the USB flash drive is manufactured using high-precision injection molds. Common materials include ABS, PC, or TPU. The injection molding process involves injecting molten plastic into a mold, which then cools and solidifies to form the housing structure. This process requires well-designed molds to ensure uniform plastic flow and avoid defects such as air bubbles, burn marks, or short shots.

Additionally, color matching and shell assembly are performed during injection molding to ensure the USB housing and internal core colors, as well as logo orientation, are consistent, enhancing product aesthetics and brand recognition. In some high-end products, soft materials (like TPE) are incorporated into the mold to improve grip and durability.

V. Assembly and Quality Control: Ensuring Functionality and Reliability

Assembly is the final critical step in USB flash drive production, involving soldering the terminals to the wires, internal structure assembly, and housing encapsulation. During soldering, high-frequency soldering machines or solder pots are used to ensure complete contact between the core wires and terminals with low resistance. After assembly, functional tests are conducted, including continuity tests, data transfer speed tests, and insertion/removal cycle tests, to ensure each USB flash drive meets design standards.

The quality inspection phase is crucial. It involves visual inspections, dimensional measurements, and electrical performance tests to screen out defective units. Production lines typically feature multiple inspection points, supported by statistical data analysis to continuously optimize the manufacturing process and reduce the defect rate.

Conclusion

The manufacturing process of a USB flash drive is a highly precise and multi-stage collaborative effort. From stamping the metal terminals and plating for enhanced durability, to injection molding the housing, and finally assembly with strict quality control, each step directly influences the final product's performance and quality. For technical engineers and production managers, a deep understanding and optimization of these processes can significantly improve production efficiency and product competitiveness.